الحار منتجات

ملكنا الإخبارية

What is the list and quota of the concrete secondary crushing set

Concrete Crushing an overview ScienceDirect Topics

2010年8月7日 The desired concrete crushing failures shown in Figs. 1.24 and 1.25 can only be achieved if IC, CDC and PE debonding can be prevented from occurring before the design load to cause concrete crushing. However, this may not always be possible; in

进一步探索Crushing or Crush Concrete Cubes or Cylinder at 28 daysConcrete Crush an overview ScienceDirect TopicsStandards for 7-day and 28-day strength test resultsCompressive Strength of Concrete after 7 and 28 days AboCompressive Strength of Concrete -Cube Test, Procedure, R根据热度为您推荐•反馈

Concrete Crush an overview ScienceDirect Topics

The concrete material properties are given in Fig. 7.5(e) where the crushing strain of the concrete ɛ c = 0.003. The flexural analysis ( Section 3.4.2.1 and Fig. 3.36 ) is illustrated

What Is Primary, Secondary, and Tertiary

2021年1月10日 The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on

Downstream Crushing Options for Secondary, Tertiary

Types of Secondary CrushersTypes of Tertiary and Quaternary CrushersChoosing The Right Secondary Crusher

Secondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crushermay be applied as a secondary crusher. Cone Crushers Cone Crushersare compression-type crushers, which reduce material as it advances downward through the chamber (with the help of gravit...

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Secondary Crushing. Secondary crushing is the second stage in the comminution process and involves breaking down the material further into smaller pieces

Secondary Crushing Equipment Mineral

2016年2月28日 The term “secondary crushing” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary

Different types of crushing equipments Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the

SecondaryTertiary Crushing Circuits Mineral

2015年7月24日 Our last schematic represents a CLOSED CIRCUIT. This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high

Making concrete Resource RSC Education

Set the cup with the concrete mixture aside as well as another polystyrene cup of water filled to about the same level as the cup with the concrete. Weigh the cup of water. Set the cup

Selecting the right type of crushing equipment

2016年4月7日 A ttrition crushers which use both impact and grinding to shear material. Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principle. Impact crushers utilise

Choosing the right crusher Buying Guides DirectIndustry

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks

Different types of crushing equipments Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and

5 Types of Concrete Crushers for Recycling Concrete Blocks

2023年2月28日 Small concrete crushers are mainly used for crushing with small output, and most of them are jaw crushers with fixed and mobile types. The feed size of the small concrete crusher is not very large, so it can only process smaller concrete materials. Small/mini jaw crusher. it is used for small size of concrete Weight:12t Capacity:1-30t/h

How Does Concrete Crushing Work? Uses of Crushed

2019年10月3日 We process the concrete into pieces 18” square to remove much possible rebar and enhance easier passage through the crusher. Then the excavator loads or pours the concrete into the crusher that break the blocks into small pieces by using its strong interlocking teeth. Once concrete processing is done, sorting of the pieces by size follows

AMIT 135: Lesson 5 Crushing Mining Mill

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

Concrete Crusher RUBBLE MASTER Construction Rubble

2023年4月5日 RM 100GO! in the middle of the action. The mobile RM 100GO! impact crusher is currently processing 40,000 m³ of steel-reinforced concrete. The material will then be reused in the construction of what will be the tallest building in Israel. The impressive throughput performance in combination with the compact design were the main reasons

Everything You Need To Know About Recycled

2020年9月14日 Recycled crushed concrete begins by breaking down original structures. This can include just about any of the normal concrete structures that would go into landfills, like building slabs, curbs,

Rock Crushing Process in Mining Mineral

2015年7月18日 secondary crushing is the second, Tertiary crushing is the third, Quaternary crushing is a rare forth stage of rock crushing, Coarse crushing includes crushing operations discharging at sizes 4- to 6-in. or

How Does a Concrete Crusher Work Training on

2023年4月3日 Eliminate construction and demolition waste on-site. Improve site productivity by removing wasted downtime between excavation removal and material replacement. See immediate savings in time, labor, and expenses when you crush and recycle on-site. Operator-friendly, easy-to-understand user interface reduces training

General guidelines for secondary indexes in DynamoDB

2 之 Each table in DynamoDB can have up to 20 global secondary indexes (default quota) and 5 local secondary indexes. For more information about the differences between global secondary indexes and local secondary indexes, see Improving data access with secondary indexes.. In general, you should use global secondary indexes rather than

Schematic description of the crushing plant, (1) primary

Based on the modern rock aggregate science and technology, secondary and tertiary crushing operations should fulfill the following requirements [1,2]: To investigate the above-mentioned statements

Selecting the right crusher for your operations

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can

Cone Crusher For Sale Secondary Crushing Equipment

1. Single-cylinder type is suitable for secondary crushing, multi-cylinder is suitable for fine crushing. 2. If you need more aggregate than fine, you can choose a single cone crusher plant. 3. It is recommended to use a multi-cylinder

Different types of crushing equipments Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and

AMIT 135: Lesson 5 Crushing Mining Mill

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

Crushing or Crush Concrete Cubes or Cylinder at 28 days

2018年4月1日 Concrete elements are designed on the basis of a 28-day cube’s crushing strength. A 28-day cube’s strength actually represents the characteristic strength of the concrete. It is mandatory to test the concrete cubes or cylinders at the age of 28 days as per almost all building code requirements. Now, once your 7-day test and even your 14-day

Everything You Need To Know About Recycled

2020年9月14日 Recycled crushed concrete begins by breaking down original structures. This can include just about any of the normal concrete structures that would go into landfills, like building slabs, curbs,

Batching Of Concrete: A Guide To Accurate Mixing

1 Batching is a critical step in the production of high-quality concrete. It involves the precise measurement and combination of the materials that make up concrete, such as cement, aggregates, water, and admixtures. The importance of batching in concrete production can be summarized as follows: 1. Consistency and Uniformity: Proper

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

How Does a Concrete Crusher Work Training on

2023年4月3日 Eliminate construction and demolition waste on-site. Improve site productivity by removing wasted downtime between excavation removal and material replacement. See immediate savings in time, labor, and expenses when you crush and recycle on-site. Operator-friendly, easy-to-understand user interface reduces training

طاحونة الملح الصانع الصين

ماشین آلات برای محصول نشاسته ژاپن

آلات نموذج الصخور mettel جديدة في الهند

لاستخراج الألومنيوم من خام غسل

ما علاج وجع الطواحين

خرد کردن گیاه غربالگری برای فروش

الميكا المعدنية تولي

معدات ثقيله مستعمله من المانيا

معدات التنقيب عن الذهب استراليا

محطم آلة العلف

رسومات 3D من فرن رمح الرأسي

الألومنيوم سحق آلة في ماليزيا

الإعداد الهند محطة كسارة

نماذج كسارة الفك والفرق

الكرة المطاحن أجزاء إعداد مكونات

ماكينات تصنيع الكسارة في ألمانيا

عکس ها از آسیاب کلوئیدی امولسیون آسفالت

معدات التعدين للبيع في أمريكا

بيع كسارة pt ton bukit golf mediterania

شركة تصنيع المحاجر والتعدين الصين

اختيار طاحونة الداخلية

بهترین دستگاه سنگ شکن سنگی در هند و قیمت آنها

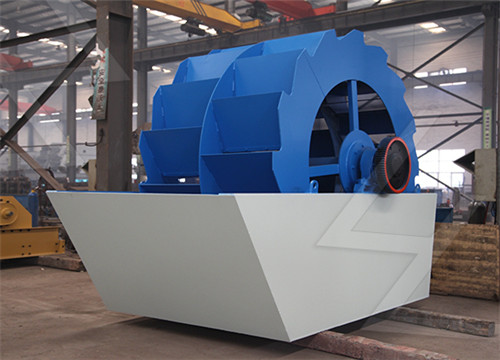

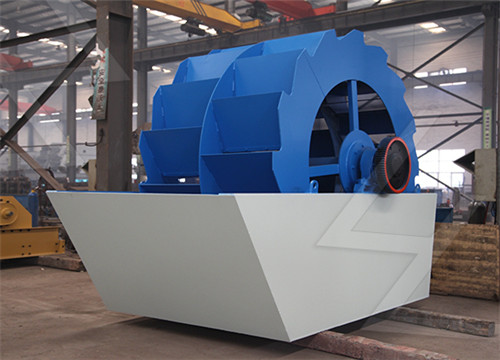

المحمول آلة غسل الرمال للبيع

كسارة الفك لخام المنغنيز

الكرة مطحنة نظرية الشعبي

كتالوج شاشة الجرانيت محطم

Concrete Crush an overview ScienceDirect Topics

The concrete material properties are given in Fig. 7.5(e) where the crushing strain of the concrete ɛ c = 0.003. The flexural analysis ( Section 3.4.2.1 and Fig. 3.36 ) is illustrated

What Is Primary, Secondary, and Tertiary

2021年1月10日 The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on

Downstream Crushing Options for Secondary, Tertiary

Types of Secondary CrushersTypes of Tertiary and Quaternary CrushersChoosing The Right Secondary Crusher

Secondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crushermay be applied as a secondary crusher. Cone Crushers Cone Crushersare compression-type crushers, which reduce material as it advances downward through the chamber (with the help of gravit...

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Secondary Crushing. Secondary crushing is the second stage in the comminution process and involves breaking down the material further into smaller pieces

Secondary Crushing Equipment Mineral

2016年2月28日 The term “secondary crushing” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary

Different types of crushing equipments Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the

SecondaryTertiary Crushing Circuits Mineral

2015年7月24日 Our last schematic represents a CLOSED CIRCUIT. This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high

Making concrete Resource RSC Education

Set the cup with the concrete mixture aside as well as another polystyrene cup of water filled to about the same level as the cup with the concrete. Weigh the cup of water. Set the cup

Selecting the right type of crushing equipment

2016年4月7日 A ttrition crushers which use both impact and grinding to shear material. Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principle. Impact crushers utilise

Choosing the right crusher Buying Guides DirectIndustry

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks

Different types of crushing equipments Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and

5 Types of Concrete Crushers for Recycling Concrete Blocks

2023年2月28日 Small concrete crushers are mainly used for crushing with small output, and most of them are jaw crushers with fixed and mobile types. The feed size of the small concrete crusher is not very large, so it can only process smaller concrete materials. Small/mini jaw crusher. it is used for small size of concrete Weight:12t Capacity:1-30t/h

How Does Concrete Crushing Work? Uses of Crushed

2019年10月3日 We process the concrete into pieces 18” square to remove much possible rebar and enhance easier passage through the crusher. Then the excavator loads or pours the concrete into the crusher that break the blocks into small pieces by using its strong interlocking teeth. Once concrete processing is done, sorting of the pieces by size follows

AMIT 135: Lesson 5 Crushing Mining Mill

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

Concrete Crusher RUBBLE MASTER Construction Rubble

2023年4月5日 RM 100GO! in the middle of the action. The mobile RM 100GO! impact crusher is currently processing 40,000 m³ of steel-reinforced concrete. The material will then be reused in the construction of what will be the tallest building in Israel. The impressive throughput performance in combination with the compact design were the main reasons

Everything You Need To Know About Recycled

2020年9月14日 Recycled crushed concrete begins by breaking down original structures. This can include just about any of the normal concrete structures that would go into landfills, like building slabs, curbs,

Rock Crushing Process in Mining Mineral

2015年7月18日 secondary crushing is the second, Tertiary crushing is the third, Quaternary crushing is a rare forth stage of rock crushing, Coarse crushing includes crushing operations discharging at sizes 4- to 6-in. or

How Does a Concrete Crusher Work Training on

2023年4月3日 Eliminate construction and demolition waste on-site. Improve site productivity by removing wasted downtime between excavation removal and material replacement. See immediate savings in time, labor, and expenses when you crush and recycle on-site. Operator-friendly, easy-to-understand user interface reduces training

General guidelines for secondary indexes in DynamoDB

2 之 Each table in DynamoDB can have up to 20 global secondary indexes (default quota) and 5 local secondary indexes. For more information about the differences between global secondary indexes and local secondary indexes, see Improving data access with secondary indexes.. In general, you should use global secondary indexes rather than

Schematic description of the crushing plant, (1) primary

Based on the modern rock aggregate science and technology, secondary and tertiary crushing operations should fulfill the following requirements [1,2]: To investigate the above-mentioned statements

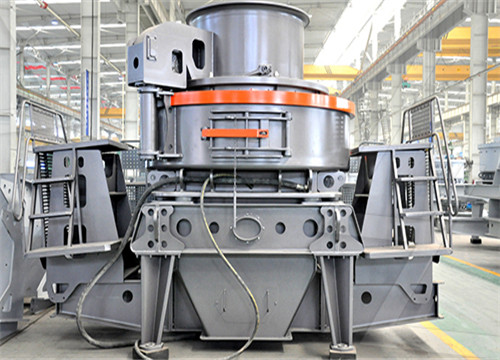

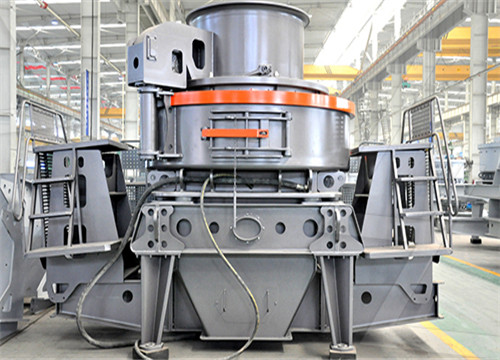

Selecting the right crusher for your operations

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can

Cone Crusher For Sale Secondary Crushing Equipment

1. Single-cylinder type is suitable for secondary crushing, multi-cylinder is suitable for fine crushing. 2. If you need more aggregate than fine, you can choose a single cone crusher plant. 3. It is recommended to use a multi-cylinder

Different types of crushing equipments Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and

AMIT 135: Lesson 5 Crushing Mining Mill

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

Crushing or Crush Concrete Cubes or Cylinder at 28 days

2018年4月1日 Concrete elements are designed on the basis of a 28-day cube’s crushing strength. A 28-day cube’s strength actually represents the characteristic strength of the concrete. It is mandatory to test the concrete cubes or cylinders at the age of 28 days as per almost all building code requirements. Now, once your 7-day test and even your 14-day

Everything You Need To Know About Recycled

2020年9月14日 Recycled crushed concrete begins by breaking down original structures. This can include just about any of the normal concrete structures that would go into landfills, like building slabs, curbs,

Batching Of Concrete: A Guide To Accurate Mixing

1 Batching is a critical step in the production of high-quality concrete. It involves the precise measurement and combination of the materials that make up concrete, such as cement, aggregates, water, and admixtures. The importance of batching in concrete production can be summarized as follows: 1. Consistency and Uniformity: Proper

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

How Does a Concrete Crusher Work Training on

2023年4月3日 Eliminate construction and demolition waste on-site. Improve site productivity by removing wasted downtime between excavation removal and material replacement. See immediate savings in time, labor, and expenses when you crush and recycle on-site. Operator-friendly, easy-to-understand user interface reduces training

طاحونة الملح الصانع الصين

ماشین آلات برای محصول نشاسته ژاپن

آلات نموذج الصخور mettel جديدة في الهند

لاستخراج الألومنيوم من خام غسل

ما علاج وجع الطواحين

خرد کردن گیاه غربالگری برای فروش

الميكا المعدنية تولي

معدات ثقيله مستعمله من المانيا

معدات التنقيب عن الذهب استراليا

محطم آلة العلف

رسومات 3D من فرن رمح الرأسي

الألومنيوم سحق آلة في ماليزيا

الإعداد الهند محطة كسارة

نماذج كسارة الفك والفرق

الكرة المطاحن أجزاء إعداد مكونات

ماكينات تصنيع الكسارة في ألمانيا

عکس ها از آسیاب کلوئیدی امولسیون آسفالت

معدات التعدين للبيع في أمريكا

بيع كسارة pt ton bukit golf mediterania

شركة تصنيع المحاجر والتعدين الصين

اختيار طاحونة الداخلية

بهترین دستگاه سنگ شکن سنگی در هند و قیمت آنها

المحمول آلة غسل الرمال للبيع

كسارة الفك لخام المنغنيز

الكرة مطحنة نظرية الشعبي

كتالوج شاشة الجرانيت محطم

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20